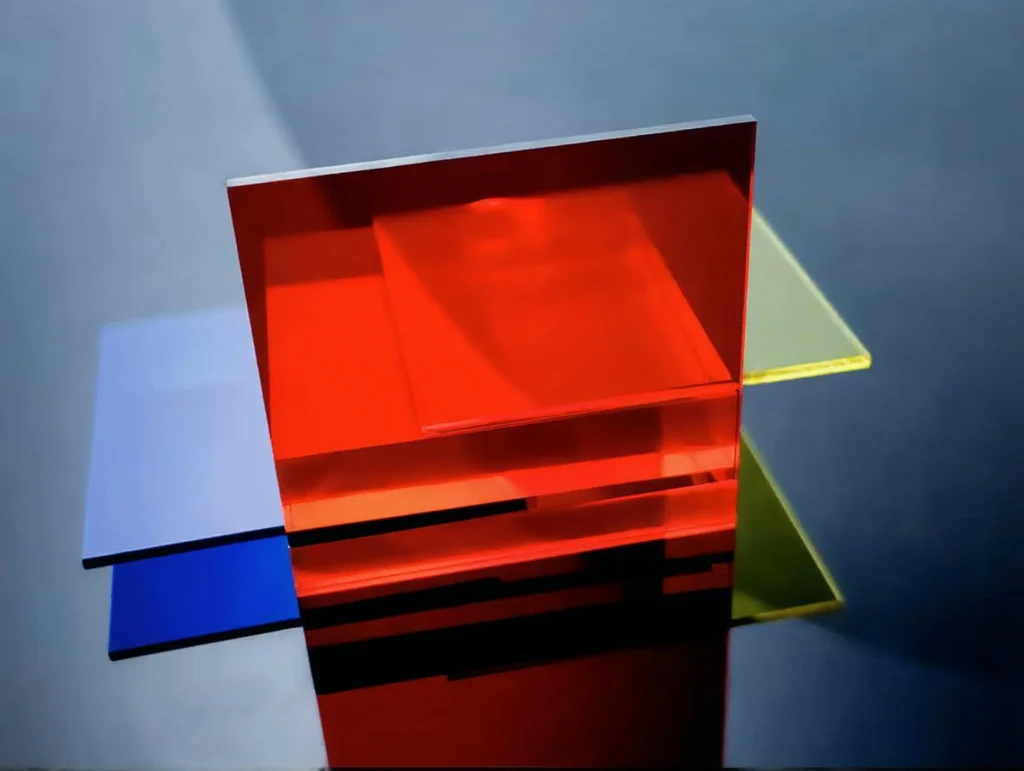

1. Raw Material

The manufacturing process begins with the use of 100% virgin plastic pellets. These high-quality raw materials are carefully selected to ensure consistent performance, durability, and a premium finish in the final product. By using only virgin pellets, we avoid contamination and ensure that every sheet is produced with the best possible foundation.

2. Feeding

The plastic pellets are transported from large storage silos into a feeding hopper positioned above the extrusion line. This process is fully automated to maintain a steady and continuous supply of material. As a result, the feeding remains uniform, material waste is minimised, and the production line operates smoothly and efficiently.

3. Hot Melting

Once inside the extruder, the pellets pass through a series of heated zones. These zones gradually increase the temperature, melting the pellets into a thick, molten mass. The controlled heating prevents burning or degradation of the material and ensures it is properly prepared for shaping. At this stage, additives or colourants may also be introduced if required.

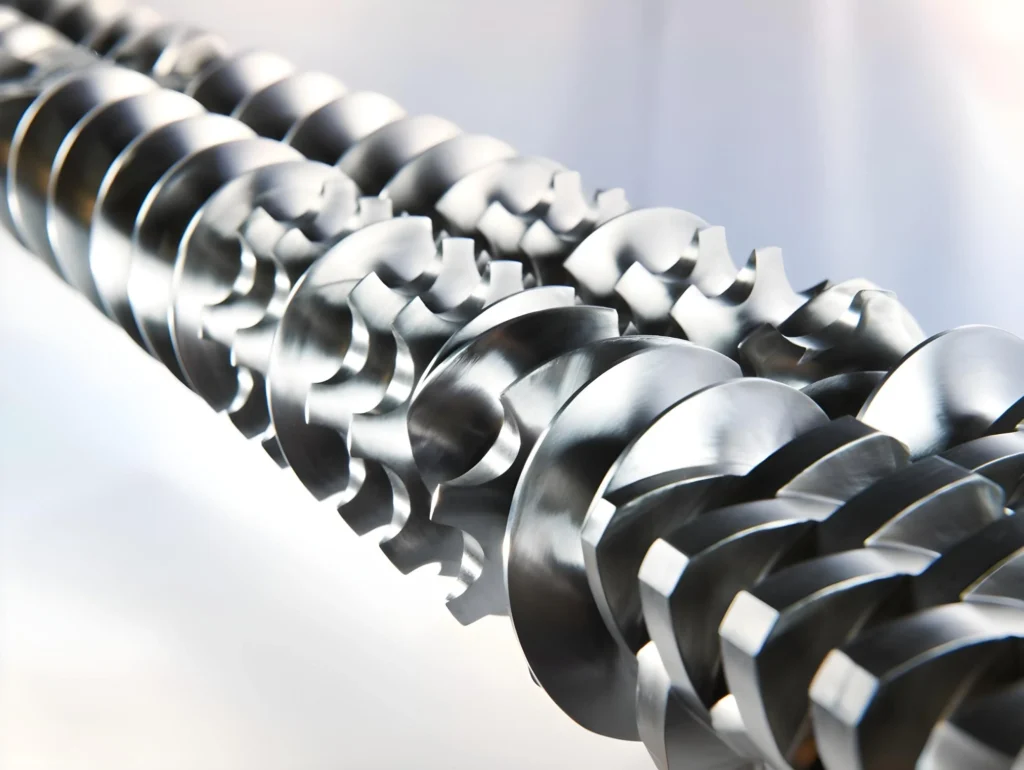

4. Extruding & Moulding

The hot, molten material is then driven forward through the extruder by rotating screws. It is forced into a specially designed conical, or cone-shaped, die where it begins to take the form of a sheet. As it exits the die, the material starts to cool slightly while retaining its shape, preparing it for the next stage of production.

5. Masking

As the sheet moves along the haul-off line, it continues to cool and solidify until it reaches a stable condition. A protective masking film or layer is then applied to the surface to prevent scratches, dust, or damage during handling and transportation. This step ensures that the final product remains clean, protected, and visually appealing.

6. Checking

Throughout the process, the sheet’s thickness and overall quality are carefully monitored. Advanced measuring systems continuously check the thickness, ensuring accuracy and consistency across the entire surface. Adjustments are made whenever necessary to meet the specified standards or customer requirements.

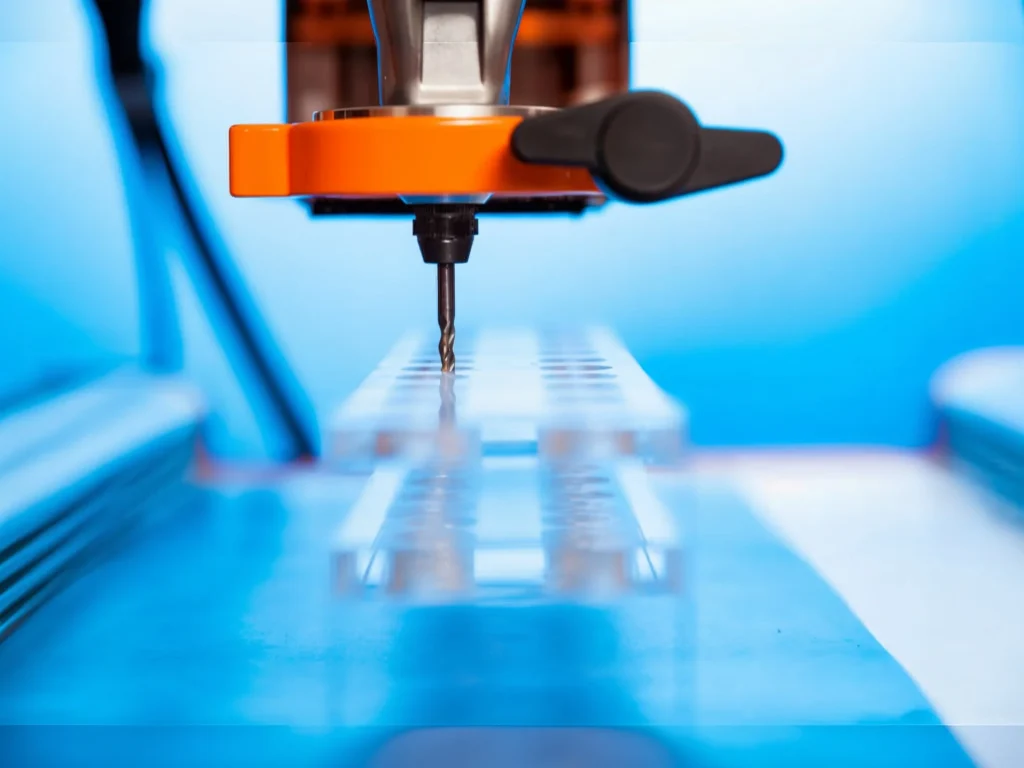

7. Cutting

Once the sheet has fully cooled and passed inspection, it is precisely trimmed along the edges to remove any excess material. It is then cut to the required final length and width using automated cutting machines. This ensures each sheet is uniform, neatly finished, and ready for packaging.

8. Stacking

Finally, the finished sheets are collected, neatly stacked, and properly aligned. They are then palletised and securely wrapped to protect them during storage and transportation. At this point, the products are ready for dispatch to customers or distribution centres.